-40%

Schneider & Marquard SK-5705 micro Hole Punching Machine/System

$ 10559.99

- Description

- Size Guide

Description

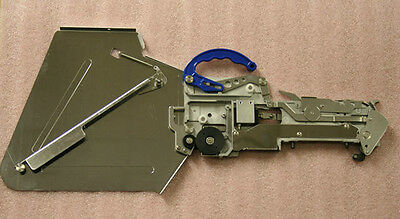

Schneider and Marquard SK-5705 Micro Hole Punching MachineComes with what you see in the pictures. If you don't see it, you probably wont get it.

Specifications are from Schneider & Marquard and may vary slightly due to upgrades, options, or revisions this unit may or may not have.

The unit has been fully tested and is guaranteed to work.

List Price for the Unit was:

6,000.00

The Serial Number Tag Readss:

Model Number:

SK-5705

Description:

Micro Hole Punching Machine

Serial Number:

039202

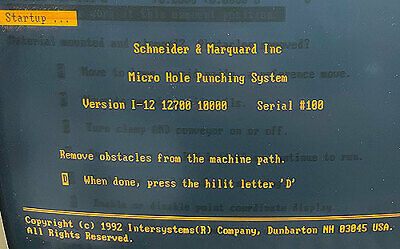

Software Information:

Version:

I-12 127000 10000

Serial Number:

100

Key Features:

User-Friendly Operation:

Simply download your DXF files, affix your part to the work holder frame, set the machine punching parameters and you are ready to run. The machine will punch your array of high quality holes, prceisely and accurately, part after part.

Fast Change-Over:

Press the raise arm button and the hinged punch arm lifts to faciliate quick and easy punch and die changes. Punches and/or dies can be changed within minutes right on the machine. No need to align die to punches; completely and reliably self-aligning.

Excellent Hole Quality:

Round, clean, burr free holes even in the thinnest of materials. Straight, smooth walls, no "cratering", "bell-mouth" or "blow-out".

Fast Production Speeds:

Punching rates of 8 to 10 holes per second on 1.0 mm moves are attainable. By linking two or more tools rates of up to 1440 holes per minute are achievable and even higher rates can be reached using "cluster" tools. Part loading and unloading is made quick and easy by a work holder frame that accepts preloaded steel frame inserts. Part change-over time is lesst han one minute.

Versatile:

Standard tool cartidges accept insets to punc holes from .0018" dia. through .375" dia in a wide array of materials - .0010" plastic film, up to .010" metal sheets, and .040" "green" tape. Square and irregular shaped hole can be punched and large cavities can be produced by "nibbling".

Accurate:

Hole to hole positional accuracy of ±.0004" is achievable over the entire punching area(on stabilized material). Hole roundness can be up to .0005" and diameters to ±.0001".

Economical:

Easy operation, minimal opertional maintenance, reliable performance, high quality resulsts, and knowledgeable, dependable techincal support - all at a competitive price.

Specifications:

Power:

115 VAC, 80 PSI-3/8" Air Line

Size:

60" wide x 36" high x 34" deep

Weight:

1400 lbs. (approx.)

Max. Punching Area:

10" in both axis

Resolution:

.00005"

Positional Accuracy:

±.0004"

Repeatability:

±.0002"

0.00 minimum for packaging, handling, and order processing. Shipping to be determined by destination.

Prior to shipment I will need to know the following information (filled out on a form that I will send you) for International Customers or Packages/Freight being Forwarded internationally. International customers may also be subject to a freight forwarder form if applicable.:

(1) Are you the end-user of this item?

(2) If you are not the ultimate end-user of the item, please state the ultimate end user's name.

(3) What is the ultimate country destination?